Servizio di fabbricazione personalizzato Taglio laser di tubi metallici ad alta precisione Servizio di saldatura, piegatura e assemblaggio

Che si tratti di telai strutturali, componenti funzionali o parti esposte visivamente, questo servizio copre l'intero processo, dal materiale grezzo del tubo all'assemblaggio finito, pronto per l'uso finale o l'integrazione.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | ssshhh 5000 |

| Lead time (days) | 35 | To be negotiated |

Features

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

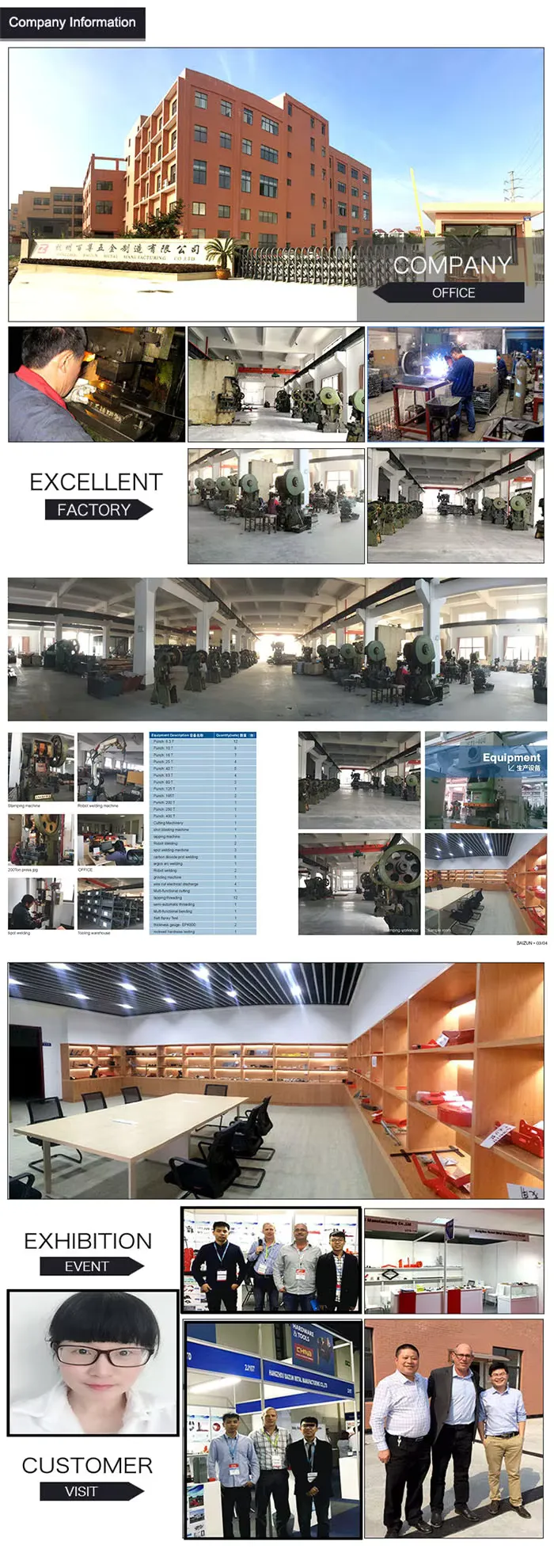

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

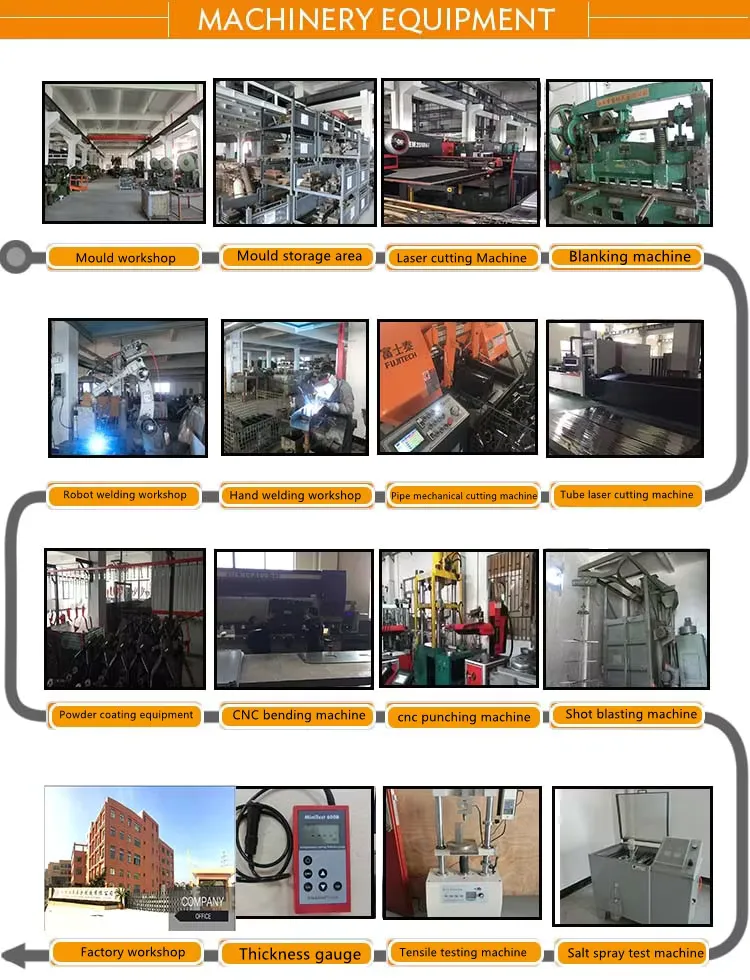

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

1. End-to-End Processing Capability

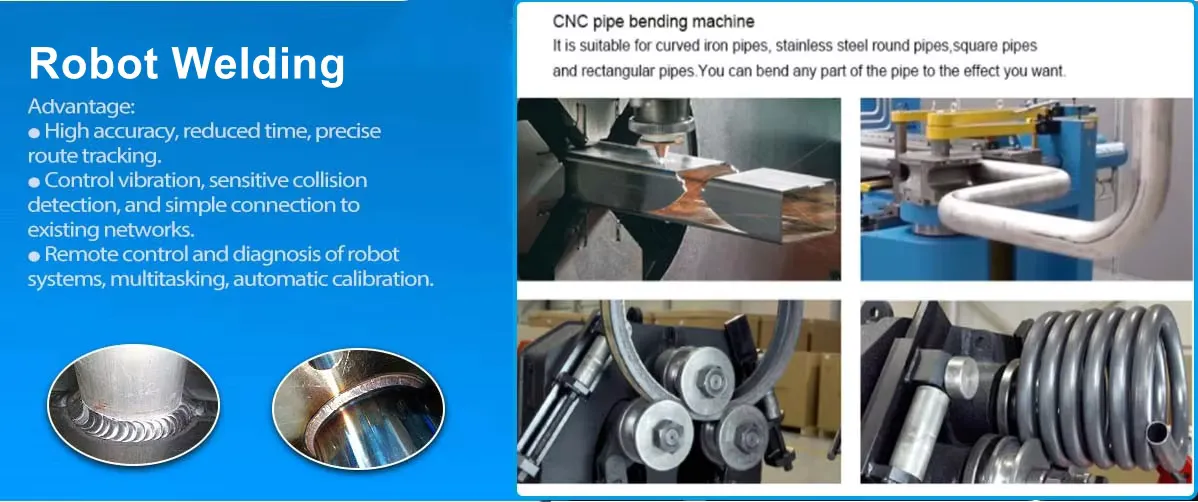

The fabrication service is structured as an all-in-one workflow. It begins with tube laser cutting, followed by CNC tube bending service, and proceeds through welding and assembly.

The CNC tube bending service provides exact shape control, reduces material waste, and supports a variety of tube geometries. Unlike manual bending, CNC ensures consistent angles, radii, and repeatability for both short-run and large-scale production.

By integrating cutting, bending, welding, and assembly under one roof, the process minimizes transportation delays and allows tighter quality control. This integrated model enhances the final product's reliability and reduces lead times for customers across industries.

2. Precision and Quality Control in Every Step

The strength of the service lies in the precision of the CNC tube bending service and the consistency of post-bending processes. After bending, each tube undergoes positioning and alignment checks before entering welding and assembly stages.

We maintain stringent quality control checkpoints at each phase, ensuring that each component adheres to the intended design. The CNC tube bending service ensures uniformity in structural alignment, avoiding deviations that may affect final assembly integrity.

Welding and joining are performed in alignment jigs or assembly fixtures to maintain the correct dimensions and angles. This coordinated system results in strong, clean welds and an overall cohesive structure.

3. Surface Treatment Compatibility

While structural integrity is the core objective, we also accommodate basic surface preparation needs post-assembly. After the CNC tube bending service and welding are completed, tube components may undergo polishing, degreasing, or coating depending on the environment they will be used in.

The consistent precision of CNC tube bending service enhances surface finish compatibility by avoiding irregular deformations or weld overlaps. This prepares the components for powder coating, painting, or other surface treatments without additional reshaping.

Surface aesthetics are often important for industries where the final product remains visible, and this service supports that need by delivering uniform, smooth metal surfaces.

4. Adaptable to a Wide Range of Applications

This fabrication service is ideal for many industry segments, particularly those that rely on structural or tubular assemblies:

Industrial machinery and enclosures

Metal furniture frames and support systems

Display racks and store fixtures

Equipment railings or protective barriers

Automotive frame and support structures

Each of these uses benefits from the accuracy and flexibility of the CNC tube bending service, which enables complex angles and durable connections with minimal parts. By using automated bending, manufacturers can reduce the number of joints and connectors, simplifying design and improving aesthetics.

5. Flexible Customization and Scalable Production

We approach each project as a custom solution. Whether you require unique dimensions, complex forms, or special assembly considerations, we adapt the process to meet your design goals.

Our CNC tube bending service supports prototype testing as well as long-term mass production. Because it’s CNC-based, tooling changes and modifications are quick and cost-effective, especially for short-run or recurring custom builds.

Throughout the fabrication process, we offer technical guidance, updates, and transparent communication. From sample confirmation to packaging and delivery, each stage is tracked for accountability and optimization.